FSD Series

The FSD series rotary screw compressor has been intelligently designed so that availability and efficiency are delivered in every operation. At AEP, we understand the importance of easy operation which is why we deem these compressors to be the perfect compressed air solution for customers looking for an innovative compressed air system that is simple to operate and service. These fully automated systems also have a distinctive, modern appearance that can integrate seamlessly into any application.

Key benefits of the FSD Series include:

- Energy-saving through every component - Every element of the FSD rotary screw compressor has been designed to be extremely energy efficient. At the core of the compressed air system is the flow-optimised and further refined SIGMA profile and the high-performance IE4 drive motor which work to deliver improved specific power.

- Partner with industrial compressed air stations - The FSD rotary screw compressors work exceptionally in high-efficiency industrial compressed air stations. The internal SIGMA CONTROL 2 compressor controller offers numerous communication interfaces (e.g. Ethernet), which, when connected within the KAESER SIGMA NETWORK, allow seamless communication with advanced master controllers, such as KAESER’s SIGMA AIR MANAGER 4.0, and in-house centralised control systems. This ensures that set-up and daily operation is simple, whilst achieving unprecedented levels of energy efficiency.

- Service-friendly design - The component layout of the FSD rotary screw compressor has been innovatively designed so that all service and maintenance points are within easy reach and are directly accessible from the front of the unit. This ensures that time and money are saved during service work, which maximises compressed air system availability.

- Electronic Thermo Management (ETM) - Powered via an electric motor, the sensor-controlled temperature control valve integrated into the cooling circuit is the heart of the innovative Electronic Thermal Management (ETM) system. By monitoring intake and compressor temperature, the SIGMA CONTROL 2 compressor controller prevents condensate formation, even under conditions with higher air humidity. FSD packages are equipped with an additional ETM system if heat recovery is used, ensuring this is adapted to the customer’s exact requirements.

FSD Series - System Specifications ...

FSD Series - Energy savings in every detail

Save energy

Save energy

At the heart of every FSD system lies a premium quality airend featuring KAESER’s SIGMA PROFILE rotors. Operating at low speed, KAESER’s airends are equipped with flow-optimised rotors for superior efficiency and performance.

Optimum efficiency

Optimum efficiency

The internal SIGMA CONTROL 2 controller ensures efficient compressor control and monitoring at all times. The large display and RFID reader provide easy communication and maximum security. Variable interfaces enable a seamless networking capability.

Tomorrow’s technology, today

Tomorrow’s technology, today

KAESER is currently the only compressed air systems provider to equip its compressors with super-premium efficiency IE4 motors as standard, thereby delivering maximum performance and energy efficiency.

Correct temperature assured

Correct temperature assured

According to operating conditions, the innovative Electronic Thermal Management (ETM) system dynamically controls fluid temperature to ensure safe prevention of condensation accumulation and also boosts energy efficiency.

...

FSD SFC Series - Compressor with variable speed drive

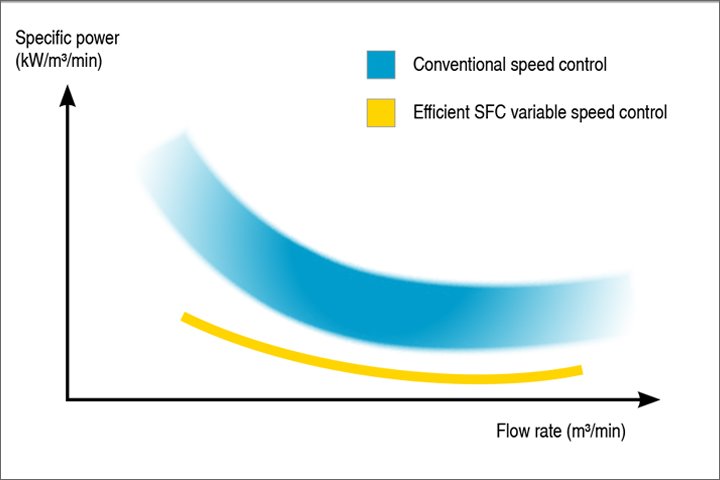

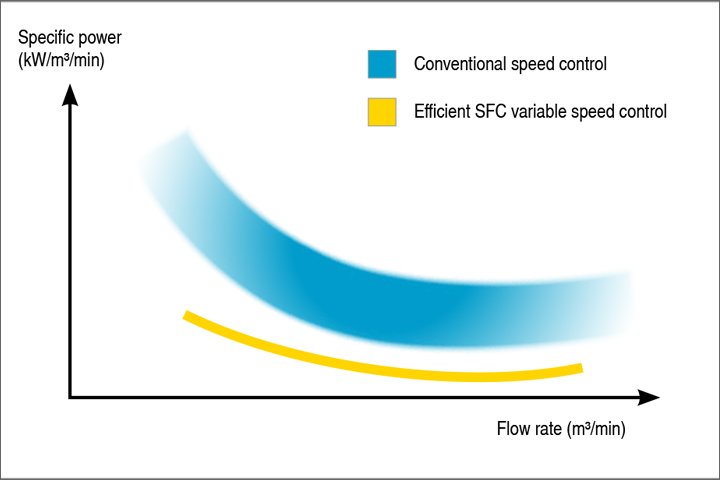

Optimised specific power

Optimised specific power

The variable speed rotary screw compressor is the most heavily loaded piece of equipment in every compressor station. FSD-SFC models are therefore designed to provide maximum efficiency without running at extreme speeds. This saves energy and maximises service life.

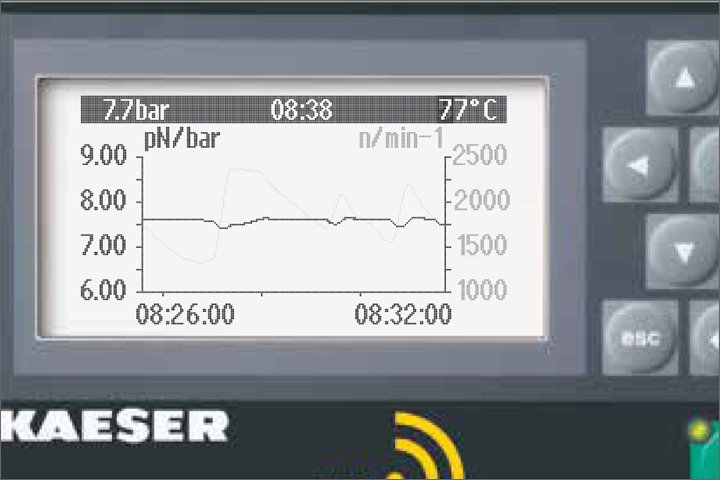

Precision pressure control

Precision pressure control

The flow rate can be adjusted within the control range according to pressure to suit actual compressed air demand. This keeps the operating pressure to within ±0.1 bar. This allows maximum pressure to be reduced which saves both energy and money.

Separate SFC control cabinet

Separate SFC control cabinet

The SFC variable speed drive is housed in its own control cabinet to shield it from heat from the compressor. A separate fan keeps operating temperatures in the optimum range to ensure maximum performance and service life from the SFC unit.

EMC-certified

EMC-certified

It goes without saying that the SFC control cabinet and SIGMA CONTROL 2 are tested and certified both as individual components and as a complete system to EMC directive EN 55011 for Class A1 industrial power supplies.