Rotary Screw Compressor - SX Series

Our customers expect our systems to provide maximum availability and efficiency from their compressors, regardless of size. The SX series rotary screw compressors meet all of these needs and more. Not only do they deliver more compressed air for less power consumption, they also combine ease of use and maintenance with exceptional versatility and environmentally responsible design.

Key benefits of the SX Series include:

- Even more compressed air in return for your investment - The SX series has even greater performance compared to previous models. This is a result of airend optimisation and minimisation of internal pressure losses. Depending on the drive power, these improvements have resulted in free air delivery of up to 14%.

- Energy-saving performance - A compressor's efficiency depends greatly on the total investment of the equipment's entire service life. The SX range has been designed to optimise its use of energy.

- Optimised design - A logical and user friendly design are aspects of all the models in this range. Visibility of the compressor components is made simple via the compressor panel that can be removed in a few simple steps.

- Modular system concept - The SX Series has three versions to cater for varied customer requirements. Following the Standard version is the T Model which is equipped with an integrated, thermally shielded refrigeration dryer. Last in this range is the AIRCENTRE which has the addition of an underslung air receiver.

SX Series at a glance ...

SX Standard - the new standard for efficiency and quiet operation

Sigma Profile Airend

Within every SX system lies a premium quality airend featuring SIGMA PROFILE rotors. HPC product engineers have managed to enhance performance and efficiency even further. The use of IE2 electrical drive motors has also contributed to additional energy savings.

SIGMA CONTROL 2

This advanced controller ensures efficient compressor control and monitoring. Communication is made simple with the generously sized display and RFID reader. Multiple interfaces for exceptional flexibility. An SD card slot makes updates quick and easy.

Even Quieter

The new cooling system combines optimum sound damping with enhanced cooling. Normal conversation can take place right next to the running compressor.

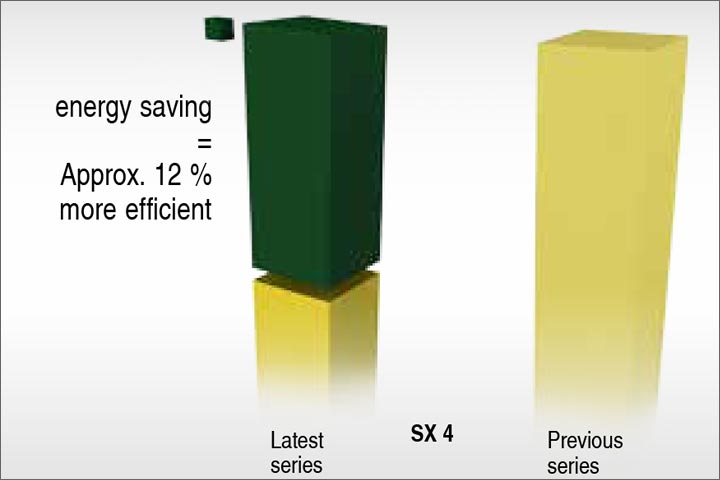

Enhanced efficiency

The new SX screw compressors are up to 12 percent more efficient than their predecessors. Based on an electricity cost of 0.20 €/kWh, this translates into energy-related savings of approximately €1,242 (for SX 4) over ten years, assuming 1,500 hours of operation annually.

...

SX 'T' - with integrated space-saving and efficient dryer

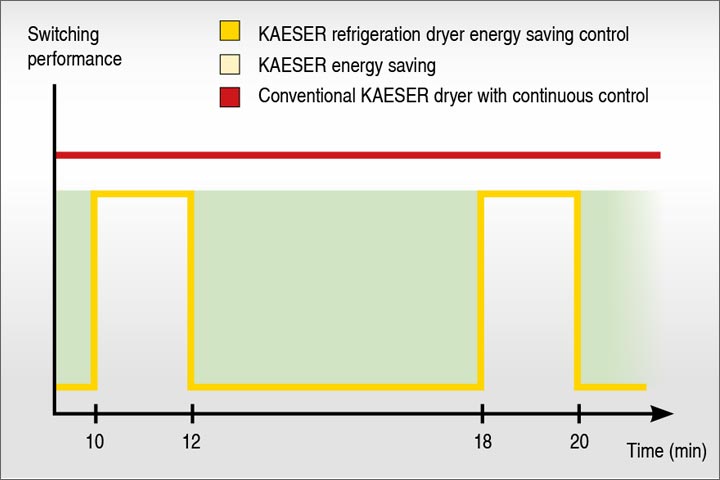

Energy Saving Control

With its innovative energy-saving control, the integrated refrigeration dryer ensures efficient operation at all times. The dryer is active only when compressed air actually needs to be dried: This approach therefore achieves the required compressed air quality with maximum efficiency.

Efficient Cooling

HPC's innovative cooling system uses a high efficiency dual flow fan and separate air flow channels for air compression, cooling air for the air/fluid cooler and the motor. This enables reliable operation in ambient temperatures of up to 45°C. The dryers in T-models feature separate cooling.

Automatic Drain

The refrigeration dryer is equipped with an ECODRAIN automatic level-sensing condensate drain that operates without pressure loss. This both saves energy and considerably enhances the reliability of the compressed air supply.

High Quality Manufacture

All rotary screw compressors and refrigeration dryers are built to Kaeser`s renowned quality standards at the company’s vertically integrated manufacturing facilities in Coburg and Gera, Germany.

...

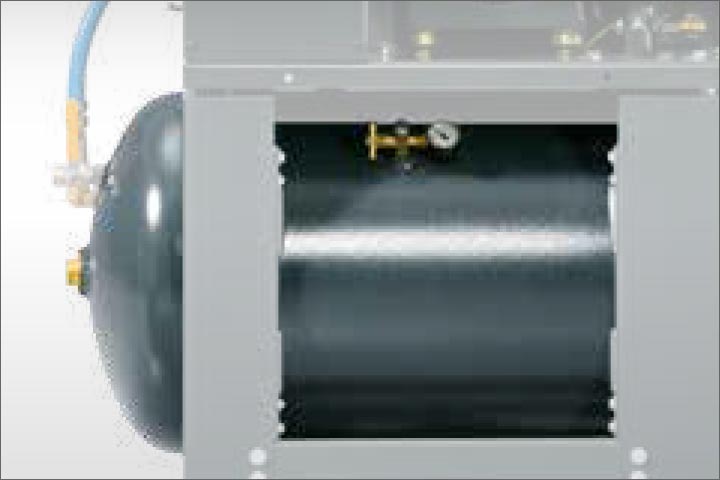

SX AIRCENTRE - the compact and efficient compressed air package

Connect and Go

Connect and Go

All this compact compressed air package needs is to be connected to the power supply and compressed air system. That’s it – no further installation work is required.

Long-lasting air receiver

Long-lasting air receiver

All Kaeser air receivers are hot-dip galvanised both internally and externally in accordance with DIN EN ISO 1461, which means they last approximately 3 times longer than conventional models.

Service-friendly design

Service-friendly design

The left-hand housing cover is easily removed to allow excellent accessibility to all service points. All models are highly compact, making them ideal for environments where space is at a premium. Inspection glasses allow convenient inspection of fluid levels and drive belt tension whilst the unit is in operation.

Excellent component access

Excellent component access

All maintenance and service components are easily accessible, which significantly reduces the downtime associated with service and maintenance tasks. This helps to increase compressed air availability and minimises operating costs.